A Near-Miss on I-295: How a TMA Truck Saved Lives

Imagine this: It’s 2:30 AM on I-295 in New Jersey. Your crew is hours into a critical milling operation. Suddenly, a drowsy driver veers into your lane at 60 mph. But instead of tragedy, the car slams into a large, clearly marked vehicle at the end of your work zone—a TMA truck. The impact crushes the rear attenuator, but your crew is unharmed. The driver, shaken, survives with only minor injuries. Your project continues with no lives lost and no headlines.

This isn’t just a story. Incidents like this happen every week on New Jersey highways—and the difference between disaster and a near-miss is often a single piece of equipment: the TMA truck.

What Is a TMA Truck?

TMA truck stands for Truck Mounted Attenuator truck—also called a crash truck or attenuator vehicle. It’s a specialized truck designed to protect road workers, drivers, and equipment from collisions in active work zones.

Components of a TMA Truck

- Attenuator (Crash Cushion): The key feature. This energy-absorbing device is mounted on the rear of the truck and designed to crumple on impact, dissipating kinetic energy and shielding people and assets ahead.

- Warning Lights & Arrow Boards: High-visibility lighting and directional boards alert oncoming traffic to lane closures or work zones.

- Heavy-Duty Chassis: Typically built on robust trucks to provide stability and withstand repeated deployments.

- Safety Features: These may include cameras, remote controls, brake lock systems, and reflective markings.

How Does a TMA Truck Work?

A TMA truck is positioned at the upstream end of a work zone, facing traffic. If a motorist fails to notice signs or loses control, the truck’s attenuator absorbs the crash, reducing the force that would otherwise hit your crew or equipment. Modern attenuators are MASH compliant—meeting the latest FHWA safety standards.

Why Are TMA Trucks Needed in New Jersey?

NJ DOT Safety Requirements

The New Jersey Department of Transportation (NJ DOT) mandates the use of TMA trucks for many highway and lane closure projects. Their requirements are clear:

“Truck-mounted attenuators are required on all mobile operations and stationary lane closures on high-speed roadways.”

— NJ DOT Traffic Control Manual

High-Risk Work Zones

New Jersey’s highways are among the busiest and most congested in the United States. Night work, short-duration lane closures, and distracted drivers create a hazardous mix. According to the U.S. Bureau of Labor Statistics, highway construction remains one of the highest-risk occupations, with hundreds of work zone fatalities nationwide each year.

A TMA truck isn’t just a box to check for compliance—it’s a proven lifesaver.

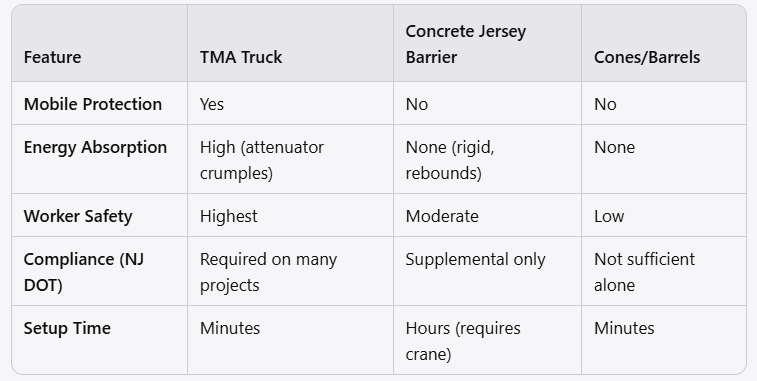

TMA Truck vs. Other Crash Barriers

Bottom line: Only a TMA truck can move with your crew, protect against high-speed impacts, and meet NJ DOT requirements for mobile and short-duration work.

Safety and Compliance: The Hard Numbers

- OSHA: 1 in 4 work zone fatalities involve a vehicle intruding into a work area.

- FHWA: Work zone crashes killed 857 people nationwide in 2022; thousands more were injured.

- NJ DOT: Requires MASH-compliant TMA trucks on most highway projects.

- Bureau of Labor Statistics: Construction laborers, flaggers, and engineers face higher rates of struck-by injuries than almost any other occupation.

TMA trucks are engineered to meet MASH (Manual for Assessing Safety Hardware) standards. These federal guidelines specify how attenuators must perform in real-world, high-speed crashes.

How to Rent or Buy a TMA Truck in NJ

Whether you need a single crash truck for a night job or a fleet of attenuator vehicles for a long-term paving project, here’s what to look for:

1. MASH Compliance

Always verify that the attenuator meets current MASH or NCHRP 350 standards.

2. Equipment Condition

Inspect the attenuator and truck. Look for recent maintenance records and verify that warning lights and arrow boards are fully functional.

3. Visibility & Signage

High-visibility paint and reflective and clear signage are a must for NJ DOT compliance.

4. Fleet Availability

Can your supplier deliver trucks quickly, especially for emergency or off-hours work?

5. Support & Service

Choose a provider who offers 24/7 support, replacement units, and operator training.

SPA Safety Systems specializes in TMA truck rentals and sales throughout New Jersey, with a fleet tailored to meet NJ DOT specifications. Visit our TMA rental page or call for a quote—you’ll get expert advice and a fast turnaround.

Conclusion: Your Crew’s Safety Depends on Your Choices

As a contractor, DOT engineer, or project manager in New Jersey, you’re responsible for more than project deadlines. Every time your crew steps onto a highway, their lives depend on your safety plan. The right TMA truck can mean the difference between a headline tragedy and everyone going home safe.

Don’t leave it to chance.

Explore SPA Safety Systems’ TMA rentals or request a custom quote today. Equip your next NJ road project with the best in safety, compliance, and peace of mind.

Sources:

FHWA MASH Guidelines, NJ DOT Safety Manuals, SPA Safety Systems Product Specs, U.S. Bureau of Labor Statistics, OSHA Work Zone Safety Resources