I saw something the other day that made me smile. It was a 12-year-old TMA truck, one we’d serviced for years, rolling into our yard for its annual inspection. The paint was faded, but the frame was solid, the hydraulics were clean, and the attenuator cartridge was in pristine condition. It passed with flying colors. That truck isn’t an accident; it’s the result of a disciplined approach to TMA truck maintenance.

In a world where safety equipment is often treated as a disposable commodity, a well-maintained TMA truck is a testament to a smart fleet manager. It’s a rolling asset that protects lives and your company’s bottom line. This isn’t about just ticking boxes on a pre-trip form. This is a field-tested playbook for keeping your most critical piece of safety equipment in service, out of the repair bay, and ready to do its job for a decade or more.

Why Proactive TMA Truck Maintenance Pays Off

Let’s be blunt: a TMA truck sitting in your yard with a hydraulic leak or a fried arrow board isn’t just an inconvenience—it’s a financial drain. Industry data shows that the average cost of downtime for a single commercial vehicle can range from $450 to over $760 per day, and that’s before you factor in the cost of project delays or fines for non-compliance.

Proactive care isn’t an expense; it’s an investment that pays dividends by:

- Maximizing Uptime: A scheduled hour of preventative maintenance saves you from days of unscheduled emergency repairs.

- Ensuring Crew Safety: The only thing worse than not having a TMA truck is having one that fails during an impact.

- Preserving Asset Value: A truck with a complete service history commands a significantly higher residual value.

- Reducing Liability: Maintaining meticulous records is your best defense in the event of an incident.

10 Maintenance Tips That Add Years Of Service

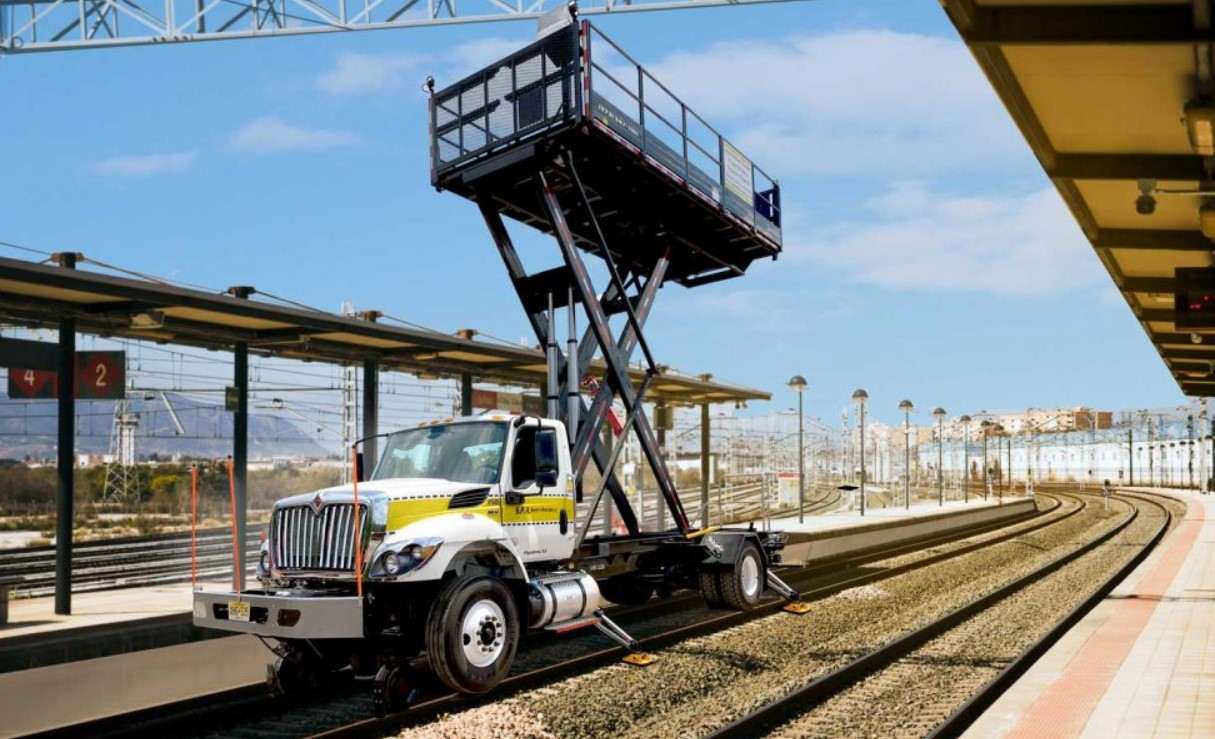

Think of your TMA truck as two separate but integrated systems: the host truck chassis and the attenuator assembly. Both require rigorous attention. Here are ten focus areas that will dramatically extend the life and reliability of your entire unit.

1. Master the Fluids & Filters Schedule

This is basic, but it’s the foundation of truck longevity. Don’t stretch intervals.

- Engine Oil & Filters: Follow the chassis manufacturer’s severe-duty schedule. Idling in a work zone is tough on an engine.

- Hydraulic Fluid & Filters: This is the lifeblood of the attenuator. Change the fluid and filter annually, or immediately if the fluid appears milky (indicating water contamination) or dark (suggesting overheating). Use only manufacturer-recommended hydraulic fluid, available through our [Parts & Repairs page].

2. Respect Cartridge & Energy Absorber Swap Intervals

The attenuator cartridge is designed for a single impact. After any hit, it must be replaced. But what about age? Over time, environmental exposure can degrade the energy-absorbing materials. We recommend a full inspection after 5 years and planning for replacement between years 7 and 10, even if there is no impact.

3. Calibrate Impact Sensors Annually

Many modern attenuators, like the Scorpion®, are equipped with sensors that trigger braking systems upon impact. These sensors must be calibrated annually to ensure they function as designed. A miscalibrated sensor could fail to activate, compromising the “roll-ahead” distance protection.

4. Hunt for Hydraulic Hose Wear

Walk the unit and physically inspect every inch of hydraulic hose. Look for cracking, chafing where hoses rub against the frame, and weeping fluid around fittings. A single burst hose can disable the entire attenuator, often at the worst possible moment. Pay special attention to the hoses that flex when the attenuator is raised and lowered.

5. Run LED Arrow Board Diagnostics Monthly

A malfunctioning arrow board is a DOT fine waiting to happen. Once a month, cycle through every pattern on your board. Replace any dim or dead LED modules immediately. Inspect the wiring harness for corrosion or damage, particularly at the connection point to the truck.

6. Sync the Brake & Suspension Systems

The massive weight of the attenuator assembly places huge demands on the host truck’s suspension and brakes.

- Suspension: Regularly inspect leaf springs for cracks and ensure airbags (if equipped) are at the correct pressure. A sagging rear suspension can alter the attenuator’s height, affecting its performance in a crash.

- Brakes: With the added weight, brakes wear faster. Adhere to a strict inspection schedule for pads, rotors, and brake fluid.

7. Clean Your Electrical Grounding Points

Gremlins in the electrical system—like flickering lights or a finicky controller—are often caused by a poor ground. There are multiple grounding points: from the battery to the frame, from the frame to the attenuator assembly, and for the lighting system. Annually, disconnect them, clean all contact points with a wire brush until they shine, and re-secure them with dielectric grease.

8. Get Aggressive with Seasonal Corrosion Prevention

For trucks operating in the snow belt, salt is the enemy. Before winter, have the truck’s undercarriage and the attenuator’s steel frame professionally undercoated. During the season, make it a point to thoroughly wash the entire unit, especially the underside, at least every two weeks to neutralize corrosive salts.

9. Follow the Tire & Wheel Torque Pattern

The host truck’s wheels bear immense weight. Improperly torqued lug nuts can lead to sheared studs and, in a worst-case scenario, a lost wheel. Always use a calibrated torque wrench and follow the manufacturer’s specified star pattern to ensure even clamping force. Check torque 50-100 miles after any wheel service.

10. Implement a Strict Post-Impact Inspection Protocol

After any impact, regardless of its severity, the truck must be immediately removed from service and inspected. According to the Federal Highway Administration (FHWA), a damaged attenuator may not provide the required protection in a subsequent crash. Your post-impact TMA repair schedule must include:

- Full replacement of the cartridge.

- Inspection of all welds on the attenuator frame.

- Checking the mounting bolts and frame of the host truck for cracks or deformation.

- A complete hydraulic system check.

Case Study: How Proactive Care Cut Costs for an NJ Paver

A (fictional) mid-sized paving contractor in New Jersey was plagued by downtime. Their two TMA trucks were constantly in the shop for emergency repairs. Following a consultation with S.P.A. Safety Systems, they implemented a rigorous maintenance plan based on these guidelines. They scheduled quarterly service and empowered their lead mechanic to perform weekly checks. The result? Within one year, they cut their emergency repair costs by 30% and eliminated project delays caused by equipment failure. Their oldest truck is now on track to deliver 12 years of reliable service.

Your Seasonal Maintenance Blueprint

To make this even easier, we’ve created a comprehensive seasonal checklist. It breaks down key inspection points for Spring, Summer, Fall, and Winter, helping you stay ahead of predictable issues.

A Critical Choice: OEM vs. Aftermarket Attenuator Truck Parts

When a repair is needed, you have a choice. Using genuine OEM (Original Equipment Manufacturer) parts versus cheaper aftermarket alternatives can have a major impact on safety and long-term costs.

|

Factor |

OEM Parts | Aftermarket Parts | The Bottom Line |

|

Fit & Compatibility |

Guaranteed to fit and function perfectly. | May require modification; tolerances can vary. | Poor fit can compromise safety and cause damage. |

|

Material Quality |

Built to the exact engineering spec for crash performance. | Materials may be of a lower grade or a different spec. |

In a crash, you need materials you can trust. |

| Warranty | Backed by the manufacturer’s full warranty. | Warranty may be limited or void the truck’s warranty. |

OEM warranty protects your investment. |

| Lifespan | Designed for maximum service life under harsh conditions. | Often have a shorter service life, leading to more frequent replacement. |

The “cheaper” option often proves more expensive in the long run. |

At S.P.A., we exclusively use and sell OEM-spec attenuator truck parts to ensure every repair restores the unit to its original safety standard.

FAQs: Maintenance Tips, TMA Crash Trucks

1. How does regular maintenance affect my TMA truck’s warranty?

Most manufacturer warranties are contingent upon following a prescribed maintenance schedule. Keeping detailed service records is essential to ensure your warranty remains valid.

2. What’s the best way to keep maintenance records?

Use a digital fleet management system or a detailed logbook for each truck. Record the date, mileage, work performed, parts used, and who performed the service. This creates an invaluable history for troubleshooting and legal protection.

3. Can telematics help with TMA truck maintenance?

Yes. Modern telematics can track engine hours (a more accurate metric than miles for TMA trucks), monitor for fault codes, and automate maintenance alerts, helping you transition from a reactive to a predictive maintenance model.

4. What are the most common repair jobs you see?

Outside of impact damage, the most frequent repairs involve the electrical system for lighting and arrow boards, followed by hydraulic leaks due to old or chafed hoses. Both are highly preventable with routine checks.

5. How often should a TMA truck be professionally inspected?

We recommend a comprehensive, professional inspection by a qualified service provider, such as S.P.A. Safety Systems, at least once a year, in addition to your regular in-house checks and daily pre-trip inspections.

Your TMA Truck is an Investment. Protect It.

Your TMA crash truck is the most important guardian of your roadside crew. Treating its maintenance as an afterthought is a risk no contractor can afford to take. By embracing a proactive, detail-oriented maintenance culture, you transform that truck from a depreciating piece of iron into a long-term, life-saving asset.

Don’t wait for a failure to force your hand. Let our experts help you build a maintenance plan that works.

Schedule a comprehensive service inspection with S.P.A. Safety Systems today and get a clear picture of your fleet’s health.

- Call Our Service Desk: (973) 347-1101

- Email Us: austin@westchestermachinery.com

- Get in Touch: Visit our [Contact Page] for more options.