Here’s a number from the Federal Railroad Administration (FRA) that every track supervisor needs to know: between 2019 and 2023, there were over 8,000 non-fatal injuries to railroad employees. A significant portion of these incidents occur during maintenance-of-way operations, where crews work against tight schedules, often just feet from active tracks. In this environment, choosing the right equipment isn’t just about efficiency; it’s a critical safety decision. The debate between using a hi-rail bucket truck versus a rail scissor truck lies at the heart of this choice. Learn more about Hi-Rail Bucket truck vs scissor in this blog post.

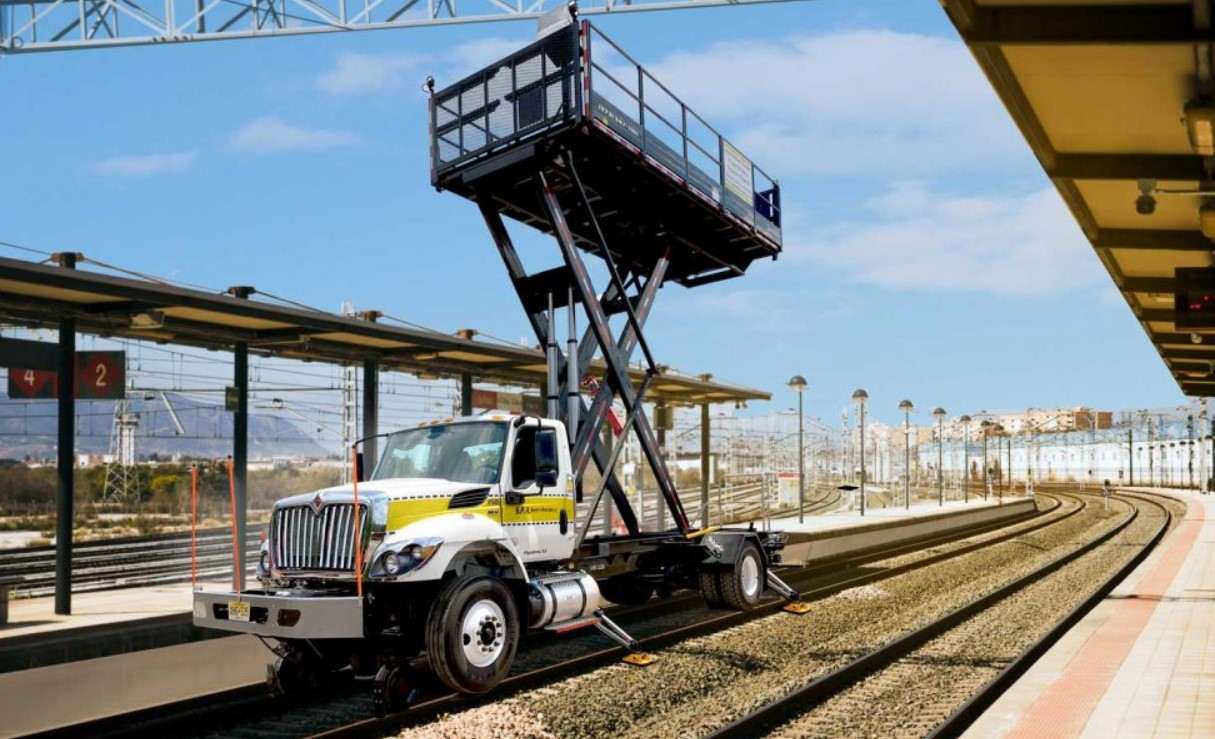

Picture two crews dispatched for an overnight replacement of catenary hardware. Crew A, using a traditional hi-rail bucket truck, positions itself. The operator carefully articulates the boom, lifting one worker and his tools up and over to the precise spot. It’s a delicate dance of controls. A few hundred yards down the track, Crew B uses a hi-rail scissor lift. They position the truck directly below the work area, raise the massive platform, and two technicians step out with all their parts and tools laid out beside them, as if on a mobile workshop floor. One job requires pinpoint reach; the other requires a stable, expansive workspace. Which is the smarter, safer choice?

As a rail-safety consultant, I’ve seen this scenario play out countless times. The answer is rarely straightforward. It depends entirely on the job, the location, and your operational priorities. This guide is designed to provide you with the strategic clarity needed to make informed decisions for your next project. Learn more about hi-rail bucket vs scissor trucks in this blog post.

Core Jobs Each Truck Must Perform

Before comparing the hardware, let’s define the mission. Both hi-rail bucket and scissor trucks are designed for elevated work along the right-of-way. Key tasks include:

- Signal Maintenance: Inspecting and replacing signal heads, bulbs, and wiring.

- Overhead Line Work: Repairing and tensioning catenary wires or other overhead power/communication lines.

- Bridge & Tunnel Inspections: Examining bridge soffits (the underside), tunnel crowns, and wall integrity.

- Vegetation Management: Trimming trees and clearing brush that infringes on the track clearance envelope.

- Station Maintenance: Repairing platform canopies, lighting, and security cameras.

While both trucks can technically perform many of these jobs, their designs make them uniquely suited for different aspects of the work.

Side-By-Side Capability Showdown: Reach vs. Workspace

The fundamental difference between a hi-rail bucket truck and a rail scissor truck comes down to a trade-off: horizontal reach versus platform capacity. One is a sniper’s rifle; the other is a fortified position.

|

Capability |

Hi-Rail Bucket Truck | Hi-Rail Scissor Truck | Strategic Implication |

|

Vertical Reach |

Excellent (40-60+ ft) | Good (25-40 ft) | For extreme heights, the bucket truck is often necessary. |

|

Horizontal (Side) Reach |

Excellent (30-40+ ft) | Very Limited (1-3 ft) | The bucket truck is the only choice for reaching up and over obstacles. |

| Platform Area | Small (~15 sq. ft) | Massive (~100 sq. ft) |

The scissor lift provides a safer, more efficient workspace for multiple crew and tools. |

| Crew & Tool Capacity | Low (400-600 lbs) | High (1,500-2,000+ lbs) |

A scissor lift can carry an entire team and their equipment, thereby reducing the number of cycles required. |

| Setup Time | Moderate (positioning & boom articulation) | Fast (positioning & vertical lift) |

Scissor lifts are generally faster to get into working position for overhead tasks. |

This table makes the choice clear: if your work is directly overhead and you can position a vehicle underneath, the hi-rail scissor lift offers a larger, safer, and more stable platform. If you must reach over an obstacle (like a second track or a barrier) or need to access extreme heights, the hi-rail bucket truck is indispensable.

Case Study: Tunnel Vision Saves Time for NJ Transit

A fictional NJ Transit crew was tasked with a rush job: replacing 50 light fixtures inside a tunnel approach with tight clearance. Their standard hi-rail bucket truck struggled; articulating the boom in the confined space was slow and risky. After two hours and only ten fixtures replaced, the foreman called for a different solution. S.P.A. Safety Systems delivered a low-profile rail scissor truck. The crew drove it into position, raised the platform, and replaced the remaining 40 fixtures in under three hours. The stable, full-width platform allowed two workers to operate simultaneously, turning a potential all-night job into a quick win.

Cost Of Ownership & Rental Economics

Whether you’re a Class I railroad or a maintenance contractor, every dollar is scrutinized. The decision to buy or rent—and which machine to choose—has significant financial implications.

Owning a specialized piece of equipment like a hi-rail bucket truck involves far more than the initial purchase price (which can easily exceed $300,000). You’re also responsible for:

- Capital Expenditure (CapEx): The massive upfront cost.

- Operating Expenses (OpEx): Fuel, insurance, and—most significantly—maintenance. Hi-rail gear and hydraulic booms require specialized technicians and frequent inspections.

- Downtime Costs: When your owned machine is down for its mandatory FRA inspection or repairs, your project comes to a halt. The cost of an idle crew quickly eclipses any potential savings.

- Depreciation & Residual Value: These complex machines depreciate quickly, and selling them requires finding a niche buyer.

Renting, particularly for short-term projects or specialized needs, flips the script. You transform a massive capital expense into a predictable operating expense. A quality rental partner, such as S.P.A. Safety Systems, handles all maintenance, inspections, and certifications. If a unit has an issue, a replacement is dispatched, minimizing costly downtime.

Illustrative 3-Year Total Cost of Ownership (TCO)

|

Cost Factor |

Owning a Hi-Rail Bucket Truck | Renting as Needed |

|

Initial CapEx |

$325,000 | $0 |

|

Annual Maintenance & Inspections |

$20,000/year (x3) = $60,000 | Included in Rental Fee |

|

Insurance & Storage |

$8,000/year (x3) = $24,000 |

Covered by General Policy |

| Estimated Downtime Costs | $15,000 (over 3 years) |

$0 (with quick replacement) |

| 3-Year Total Cost | $424,000 |

Varies by usage (e.g., $180,000) |

| Residual Value after 3 Years | ~$175,000 |

N/A |

| Net Cost of Ownership | ~$249,000 |

~$180,000 |

This simplified table shows that unless your utilization rate approaches 80-90%, renting specialized rail maintenance truck rentals is often the more financially prudent strategy.

The Safety & Compliance Lens: Beyond the Basics

Operating on a live railroad is one of the most hazardous work environments imaginable. Compliance isn’t optional; it’s the barrier between a smooth project and a catastrophe.

Key regulations include:

- FRA Part 214 (Roadway Worker Protection): This is the foundational rule for on-track safety, governing how you get authority to occupy a track and how you protect your crews.

- OSHA 1926.453 (Aerial Lifts): This standard outlines the safe operation of aerial lifts, including operator training, pre-shift inspections, and fall protection requirements.

- AREMA Guidelines: The American Railway Engineering and Maintenance-of-Way Association provides industry best practices that often exceed minimum federal requirements, covering everything from hi-rail gear design to hydraulic system integrity.

A superior rental partner ensures their fleet meets these standards and more. At S.P.A. Safety Systems, every one of our [Hi-Rail Trucks] undergoes a rigorous, multi-point inspection before every rental. We ensure that all FRA-mandated hi-rail certifications are up to date and that every lift meets or exceeds the latest ANSI/SAIA A92 standards for design and safety.

Decision Matrix: Which Hi-Rail Truck Fits Your Project?

Use this matrix to guide your thinking. Score your project’s needs against the strengths of each truck.

|

Project Factor |

Hi-Rail Bucket Truck | Hi-Rail Scissor Truck | Best Fit |

|

Work Type |

Up-and-over reach needed | Directly overhead work | Depends on task geometry |

|

Clearance Limits |

Boom can be problematic | Excellent for tunnels/bridges | Scissor Truck for low clearance |

| Work Area Footprint | Can work from the adjacent track | Must be directly below work |

Bucket Truck for multi-track areas |

| Crew & Tool Needs | 1 worker, limited tools | 2-3 workers, heavy tools |

Scissor Truck for large crews/gear |

| Budget Priority | Higher rental/ownership cost | More economical for overhead work |

Scissor Truck for budget focus |

A Note on the Hi-Rail Bucket Truck’s Unique Strengths

While this guide highlights the scissor lift’s advantages in specific scenarios, the hi-rail bucket truck remains the undisputed champion of versatility. Its ability to reach locations that are otherwise inaccessible makes it a cornerstone of any comprehensive rail maintenance fleet.

FAQs: Hi-Rail Bucket Vs Scissor Trucks For Rail Work

1. What kind of operator training is required?

OSHA requires that only trained and authorized personnel operate aerial lifts. While your team should have general certification, S.P.A. provides a detailed machine-specific familiarization upon delivery to ensure your operator is comfortable with our unit’s controls and safety features.

2. What are the insurance requirements for renting?

You will need to have a satisfactory general liability policy and provide a certificate of insurance naming S.P.A. Safety Systems as additionally insured and loss payee.

3. How fast can you deliver a truck in an emergency?

We specialize in rapid response. For emergency rail maintenance truck rentals in the New Jersey, New York, and Pennsylvania region, we can often have a unit on-site within 24 hours.

4. Does it make sense to have a mixed fleet?

Absolutely. Many of our most strategic clients maintain a small fleet of common trucks and rent specialized equipment, such as hi-rail scissor lifts or larger bucket trucks, only when a specific project demands it.

5. What happens if a rental unit breaks down on track?

Our rental agreement includes 24/7 emergency service. We will dispatch a technician immediately. If the unit cannot be repaired quickly, we will mobilize a replacement truck to minimize your downtime.

The Right Tool for the Track

The pressure on railroad maintenance crews has never been higher. You’re expected to do more with less, faster than ever before, all while maintaining an uncompromising standard of safety. Choosing between a hi-rail bucket truck and a rail scissor truck isn’t a trivial decision—it’s a strategic choice that impacts project efficiency, budget, and most importantly, the well-being of your crew.

By analyzing the specific demands of your job—reach, workspace, location, and crew size—you can move beyond “the way we’ve always done it” and select the piece of equipment that is purpose-built to make your project safer and more productive.

Don’t guess. Get expert advice. Contact the rail equipment specialists at S.P.A. Safety Systems today to discuss your next project.

- Call Us Directly: (973) 347-1101

- Email Our Team: austin@westchestermachinery.com

- Explore Our Fleet: Visit our [Contact Page] for more details.