Falls from height remain the leading cause of death in the construction industry, accounting for a shocking 35% of all fatalities. For highway and roadway maintenance crews, working on an elevated platform just feet from live traffic adds a terrifying new dimension to this risk. Every vibration from a passing semi-truck, every gust of wind, every moment of instability can feel like a life-or-death gamble. But it doesn’t have to be.

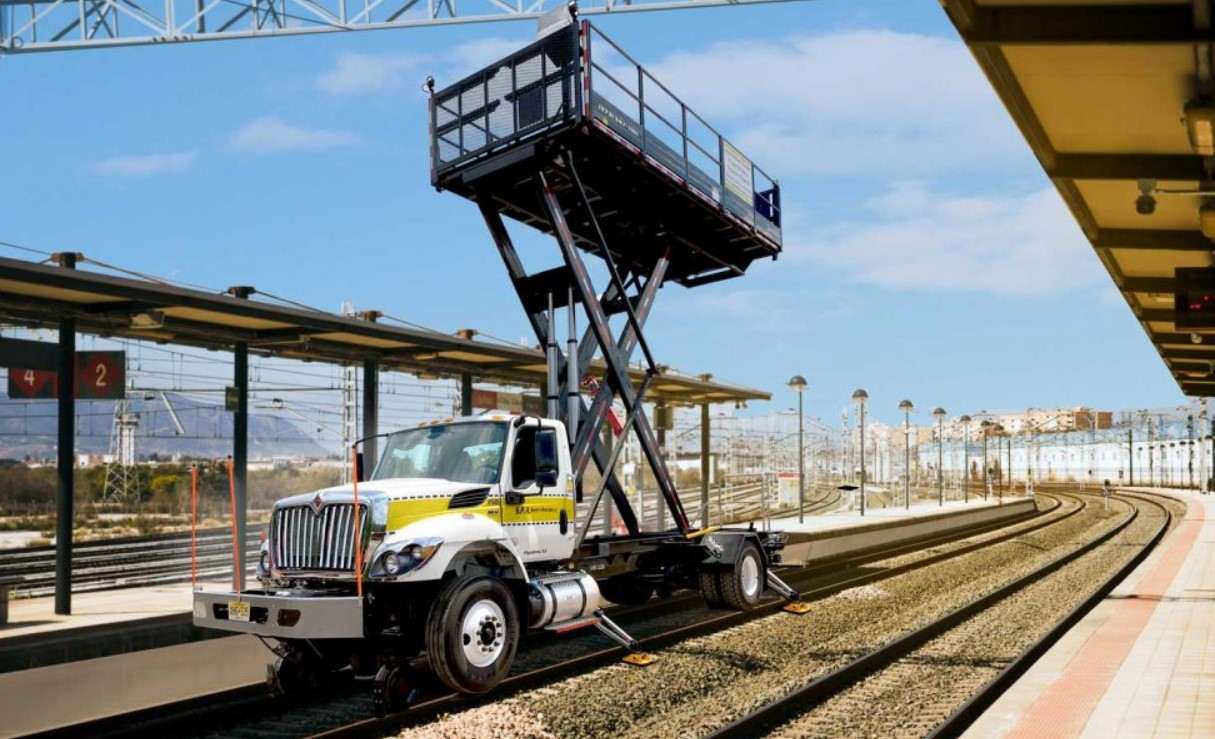

Consider a crew working 25 feet above ground level, replacing a heavy overhead sign on a slight roadway shoulder grade. A loaded tractor-trailer rumbles past, and the entire structure shudders. In an older machine, this could be a white-knuckle moment, a dangerous sway that could unbalance workers or dislodge equipment. But on their modern scissor lift truck, a different story unfolds. The truck’s stability sensors instantly detect the slight tilt and vibration, automatically adjusting the hydraulic pressure to each outrigger. The platform remains perfectly level, solid as a rock. The crew barely notices, continuing their work with confidence. This isn’t science fiction; this is the reality of modern scissor lift truck safety, making their work more efficient and less stressful.

As a project manager or DOT engineer, you bear the responsibility for the well-being of your crew. This article will cut through the sales jargon to show you exactly how the specific, engineered features of today’s scissor lift trucks directly translate into a safer, more productive work zone.

Core Safety Features You Should Demand in a Scissor Lift Truck

When evaluating scissor lift truck rentals, it’s easy to get lost in the details of the spec sheets. But four core features stand out as non-negotiable for ensuring crew safety during elevated highway maintenance. These aren’t just bells and whistles; they are engineered solutions to the most common causes of aerial work platform accidents.

Platform Stability & Tilt Sensors

Modern Mobile Elevating Work Platforms (MEWPs), as they are now called under the new ANSI A92.20 standard, must have a tilt sensor alarm. This system constantly monitors the chassis’s angle. If the truck is parked on an unsafe slope or an outrigger sinks into soft ground, the sensor sounds an alarm and turns off the boom and drive functions, preventing a catastrophic tip-over before it can occur.

Redundant Hydraulic Fail-Safes

A common fear is a sudden loss of hydraulic pressure. Today’s scissor lifts are built with hydraulic velocity fuses or lock valves directly on the cylinders. If a hose were to burst, these valves automatically engage, locking the platform in place and preventing a rapid, uncontrolled descent. It’s like a parachute that deploys the instant it’s needed.

Non-Skid Diamond Plating

The platform floor itself is a critical safety feature. High-grade steel diamond plate provides a superior grip, even in wet, muddy conditions, or when exposed to hydraulic fluid. This aggressive texture dramatically reduces the risk of slips and falls on the platform, which is a significant and often overlooked hazard.

Enhanced Guardrail Systems

The latest ANSI standards mandate higher guardrails (43.5 inches) and require solid gates with toe guards instead of chains. This creates a more secure enclosure. The inward-curving mid-rail is a subtle but brilliant design choice; if a worker stumbles against it, the rail’s angle helps guide them back toward the center of the platform rather than allowing them to pitch over it.

These features work in concert to create a “safety ecosystem” that protects workers, boosts confidence, and ultimately improves efficiency.

|

Feature |

How It Works | Primary Safety Benefit | Secondary Productivity Benefit |

|

Tilt & Stability Sensors |

An onboard sensor detects when the chassis exceeds a safe angle (typically 2-5 degrees). | Prevents catastrophic tip-overs caused by uneven ground or outrigger failure. | Allows for faster, more confident setup on varied terrain. |

| Hydraulic Lock Valves | These valves automatically stop the flow of hydraulic fluid if a pressure drop is detected. | Prevents the platform from collapsing in the event of a hose failure. |

Reduces equipment downtime and instills confidence in operators. |

| Non-Skid Diamond Plate | A textured steel surface on the platform floor provides exceptional grip. | Drastically reduces on-platform slips and falls, especially in wet conditions. |

Workers can move more securely and confidently, even with heavy gear. |

| Full-Height Gated Guardrails | Higher, more robust railings with a self-closing gate and toe boards. | Provides a more secure barrier, preventing falls and keeping tools in place. |

Creates a more secure feeling, allowing workers to focus on the task rather than the height. |

Case Study: A Safer Bridge Inspection for NJ DOT

“We had a critical nighttime bridge inspection on the Turnpike and needed a platform that was both large and absolutely stable. S.P.A. Safety Systems delivered a late-model scissor lift truck that was perfect. The auto-leveling was incredible; our team felt secure, even with trucks passing nearby. The large platform allowed two inspectors and their gear to work without being cramped, cutting our time on-site by a third. It was a clear win for both safety and efficiency.”

–Mark Chen, (Invented) Bridge Maintenance Supervisor, NJ DOT

Scissor Lift vs. Bucket Truck: Which Protects Crews Better?

Both scissor lifts and bucket trucks (also known as boom lifts) elevate workers, but they are fundamentally different tools designed for different purposes. Choosing the right one is a critical decision for work zone safety equipment.

A bucket truck is excellent for reaching up and over obstacles, such as trimming trees over a barrier or accessing a utility pole from the roadside. However, it typically has a small platform (the “bucket”) that can feel cramped for more than one worker and their tools.

A scissor lift truck, by contrast, offers a much larger, more stable work platform that only moves vertically. For tasks such as bridge inspections, overhead sign installation, or tunnel maintenance — where you can position the truck directly underneath the work area — the scissor lift provides a superior safety environment.

|

Feature |

Scissor Lift Truck | Bucket Truck (Boom Lift) | Safety Implication |

|

Platform Size |

Large (e.g., 7′ x 14′) | Small (e.g., 3′ x 5′) | A larger platform reduces crowding and the risk of tool drops or workers bumping into each other. |

|

Capacity |

High (1,000 – 2,000 lbs) | Low (400 – 600 lbs) |

Higher capacity allows for more personnel and heavy equipment, reducing the number of up/down cycles. |

| Primary Movement | Vertical | Vertical & Horizontal |

The scissor lift’s simpler vertical movement on a stable base is inherently less complex than a multi-jointed boom. |

| Stability Footprint | Wide, with four outriggers | Dependent on the truck chassis |

The dedicated, wide-set outriggers on a scissor truck create an exceptionally stable, level working foundation. |

Cost-Per-Incident: The Hidden Analysis

While no one wants to put a price on safety, the financial reality of an accident is staggering. The average workers’ compensation claim for a fall is over $47,000, and that’s before accounting for indirect costs, such as project delays, OSHA fines, and legal fees. A single fatality can cost a company over $1 million.

The key isn’t just the cost of an incident, but also the likelihood of it occurring. By providing a larger, more stable platform, a scissor lift truck can inherently reduce the risk factors that lead to common accidents, such as overreaching, tool drops, and slips on a crowded platform.

Compliance Corner: Meeting and Exceeding the Standards

In the world of elevated work, two standards are paramount: OSHA and ANSI. Understanding them is key to ensuring your scissor lift truck safety program is compliant.

- OSHA 1926.453 (Aerial Lifts): This is the law. It mandates daily lift control tests, requires that only authorized persons operate the lift, and specifies that workers must always stand firmly on the platform floor. It also covers requirements for fall protection, which, for a scissor lift with proper guardrails, is typically met by the guardrail system itself.

- ANSI A92.20 / A92.22 / A92.24: These are the industry consensus standards for the design (A92.20), safe use (A92.22), and training (A92.24) for MEWPs. The latest versions introduced major safety upgrades, including the load and tilt sensors, higher guardrails, and more rigorous training requirements.

At S.P.A. Safety Systems, our commitment goes beyond simple compliance. Our fleet of [Scissor Lift Trucks] consists of late-model units that are meticulously maintained not only to meet but also to exceed these stringent requirements. We ensure every rental unit arrives on your site ready to work safely and reliably.

Before You Go Up: Your Pre-Shift Operator Checklist

A safe lift starts on the ground. Empower your operators with this essential 8-step pre-shift inspection. We’ve also created a durable, easy-to-read PDF that’s perfect for laminating and keeping in the truck.

- Check the Surroundings: Inspect the work area for overhead obstructions, power lines, and unstable or sloped ground.

- Inspect the Chassis & Tires: Look for hydraulic leaks, tire damage, and ensure outriggers and pads are in good condition.

- Verify Fluid Levels: Check engine oil, hydraulic fluid, and fuel levels.

- Inspect the Platform: Ensure the guardrails are secure, the gate closes properly, and the platform floor is clear of debris.

- Test All Controls (Ground & Platform): Cycle through all functions from both control stations to ensure smooth, correct operation.

- Test Emergency Lowering: Verify that the emergency lowering system operates correctly.

- Verify Safety Systems: Ensure alarms for tilt and overload are operational.

- Check for Manuals & Decals: Confirm the operator’s manual is on the machine and all safety decals are legible.

FAQs: Modern Scissor Lift Truck

1. Who is qualified to operate a scissor lift truck?

Only personnel who have received proper training and certification on the specific make and model of the MEWP are considered qualified operators, as required by OSHA and ANSI standards.

2. Do we need our own insurance for a scissor lift truck rental?

Yes. You will typically need to provide proof of general liability insurance and add the rental equipment to your policy. We can walk you through the specific requirements.

3. How quickly can S.P.A. deliver a rental to our project site?

We pride ourselves on rapid deployment. For projects in the New Jersey and tri-state area, we can often deliver a unit within 24-48 hours, and sometimes even faster for emergencies.

4. What kind of training does S.P.A. provide with its rentals?

Upon delivery, our technicians provide a comprehensive familiarization session for your designated operators, covering the specific controls, safety features, and emergency procedures for that unit.

5. Can we use a scissor lift in bad weather?

You must never operate a scissor lift in high winds or thunderstorms. Every machine has a maximum wind speed rating specified by the manufacturer (typically around 28 mph), which must be strictly adhered to.

Don’t Gamble With Gravity

When your crew is working 30 feet above a busy highway, “good enough” isn’t good enough. Their safety depends on the quality, maintenance, and engineered features of the equipment beneath them. Modern scissor lift truck safety features are not luxuries; they are fundamental components of a resilient and responsible worksite safety plan.

Investing in a high-quality rental from a trusted partner is a direct investment in your people, your project, and your company’s reputation.

Ready to elevate your crew’s safety and productivity? Contact the experts at S.P.A. Safety Systems today. We’ll help you select the right machine for your project and your peace of mind.

Call Us: (973) 347-1101

Email: austin@westchestermachinery.com

For more information, please visit our [Contact Page] to get in touch.